- TOP

- Sasakura’s Technologies

- Evaporating Concentrator Case Study

- Fluorine Recovery Case Study

Sasakura’s Technologies

Evaporating Concentrator Case Study

CASE

Fluorine Recovery Case Study

- Issue

- We want to recover hydrofluoric acid water from hydrofluoric acid wastewater and achieve zero emissions of fluorine.

The coagulation sedimentation method using slaked lime generates a large amount of sludge from highly concentrated hydrofluoric acid wastewater, increasing industrial waste.

In addition, wastewater processed with coagulation sedimentation still contains several tens of ppm of fluorine, which imposes a heavy load on wastewater treatment.

Sasakura has developed a practical system for recovering fluorine from such liquid waste as hydrofluoric acid at more than 10% by evaporative concentration.

【Unique System】

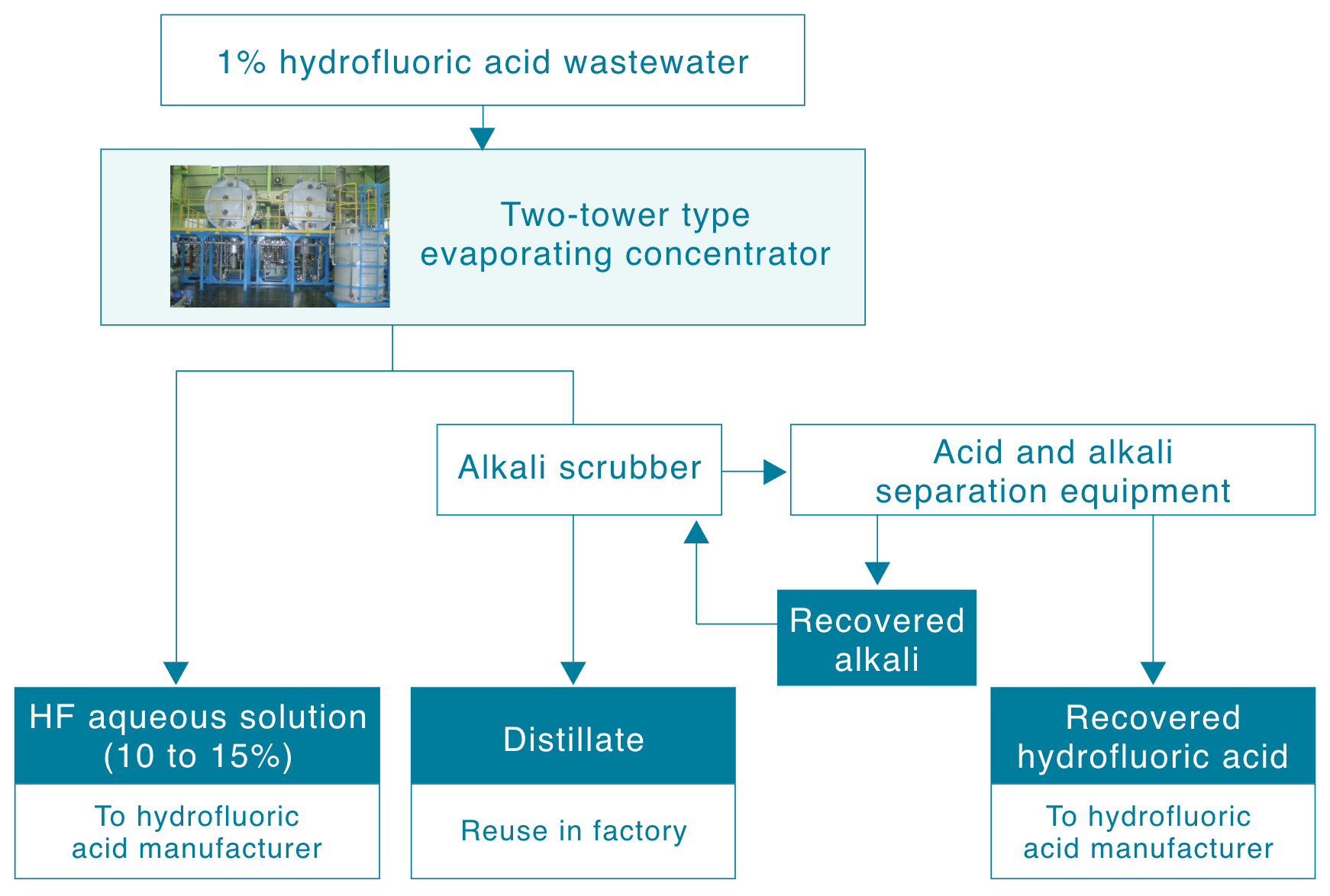

● Two-tower type concentrator

Hydrofluoric acid has the property of evaporating with water vapor, and if it is simply boiled down, most of the fluorine will evaporate away.

Two-tower type evaporating concentrators consist of a concentrator in the first tower and a water rinsing tower in the second, and the hydrofluoric acid recovered in the water rinsing tower in the second tower is fed back into the concentrator in the first tower.

This maximizes the recovery rate of hydrofluoric acid.

● Acid and alkali separation equipment

The vapor that passes through the second tower, the water rinsing tower, reaches the alkali scrubber where residual hydrofluoric acid in the vapor is removed by chemical reaction. The generated alkaline fluoride solution is again separated into hydrofluoric acid and alkali by acid and alkali separation equipment.

Solved with STC concentrator!

〈When using Model STC〉

Benefits of Introduction

- Recovery of hydrofluoric acid by evaporative concentration

- 98% recovery rate

- Reaches fluorine concentrations of 0.1 ppm or less in distilled water

- Distilled water reuse as pure water

- Zero fluoridated wastewater

- No sludge generation

Point

- Applicable concentrations of hydrofluoric acid wastewater for this method range from several thousand ppm to several tens of thousands of ppm.

- In this method, hydrofluoric acid is concentrated and recovered as hydrofluoric acid solution for use in other industries.