- TOP

- Sasakura’s Technologies

- Evaporating Concentrator Case Study

- Salt Manufacturing Process Case Study

Sasakura’s Technologies

Evaporating Concentrator Case Study

CASE

Salt Manufacturing Process Case Study

- Issue

- We want to reduce fuel costs in the salt manufacturing and concentration process.

In the conventional salt manufacturing and concentration process, a large amount of steam was required for evaporation, thus generating a large amount of waste heat.

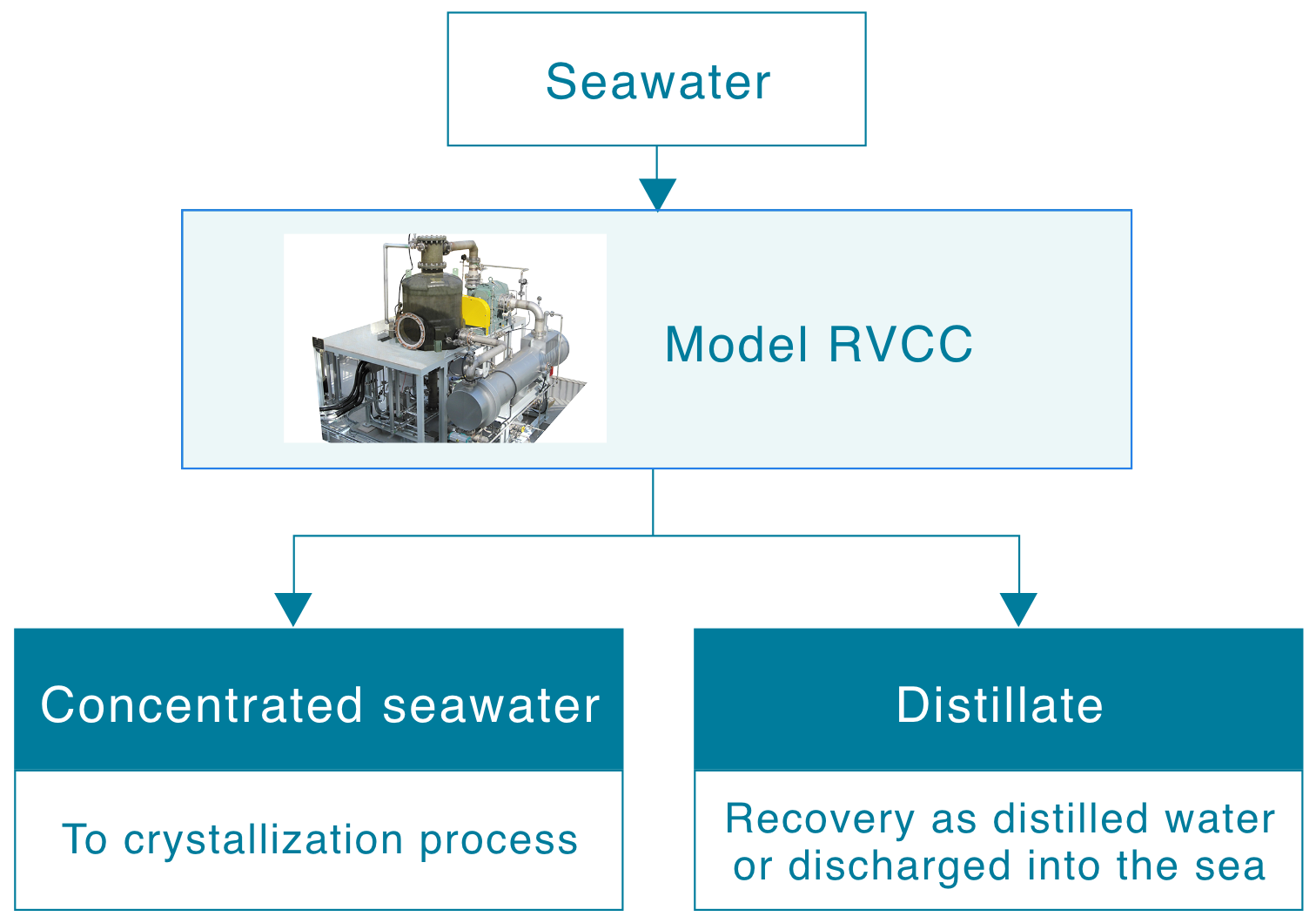

With Sasakura’s Model RVCC, steam generated from seawater is compressed by an energy-saving, high-efficiency heat pump and reused as a heating source, which significantly reduced running costs.

And since the condensate is distilled water, it can be reused as a utility.

Solved with Model RVCC!

〈When using Model RVCC〉

Benefits of Introduction

- Reduces fuel costs

- Reduces CO₂ emissions

- Reduces running costs for concentration process

- We have examples in salt manufacturing processes using this equipment

Point

- Other notable examples in the food industry include concentration of chicken and pork extracts, tea, juices, and more. Sasakura’s concentrators use heat pumps to recover heat, making steamless operation possible. This can significantly reduce running costs and CO₂ emissions.